Installation Instructions

- All standard American clothes dryers have an exhaust port in the center of the rear panel at the very bottom. Therefore, it is best to install the Dryerbox® as low as possible so that the bottom tab is at or slightly below the finished floor level (Diagram A)—not applicable if stackable unit or on a pedestal.

- Attach Dryerbox® to stud and bottom plate at a minimum of 3 corners.

- This Dryerbox is designed to accommodate an upward exhaust direction. Optionally this unit can be mounted in a downward exhaust direction for a stacked dryer or one on a 13 inch pedestal. A lying-on-its-side orientation is also an option. For floor standing dryers venting down, the Model 4D or 3D are recommended.

- When installing the 4 ¼” deep Dryerbox® (Model 425) into a 2x4 wall, fir out the respective wall ¾” with a 1x2 furring strip to provide adequate depth or use the 3 ½” Model 350.

- When installing in an exterior frame wall, you should add insulation or duct board to the back-side of the box to minimize condensation and temperature transfer.

- To achieve a fire resistance rating (one-hour F & T) min. 2X6 wood or metal framing is required. The Dryerbox unit must be installed in accordance with the UL Cabinet System listing. An extra layer of type-X drywall must be installed in the ID of the stud cavity in which the Dryerbox is located. Drywall must be attached to nailers (minimum 1” X 2”) located on the inside of the cavity wall studs. Secure nailers to wall framing

at max 18 in. OC. The screws used to attach the inner layer of drywall shall be spaced a maximum of 18 inches apart. For metal studs, mineral wool (min density 4 pcf) must fill the entire Dryerbox wall cavity and minimum R13 Fiberglass insulation in adjacent cells. For wood studs, mineral wool or R19 Fiberglass insulation must fill the Dryerbox cavity. Visit www.dryerbox.com/firestop for more detail.

- Gas line termination options: For black iron pipe, wrap vinyl tape around throat where it penetrates. For corrugated stainless steel tubing, secure the CSST Termination Fitting with a Jamb nut to securely affix the termination to the receptacle. The gas port can be enlarged or relocated easily with a step bit.

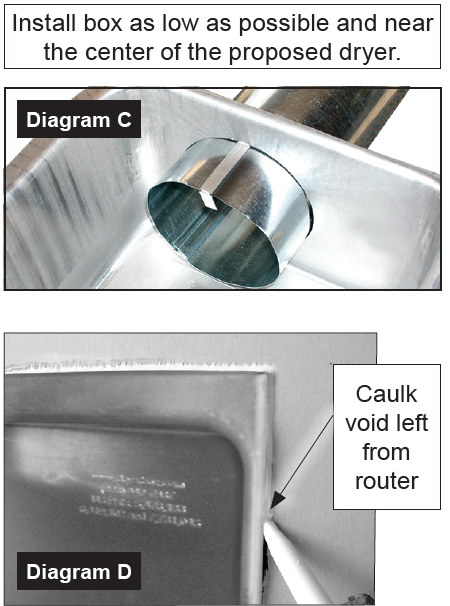

- The new Duct Support Tab (Diagram B) in top port will assist in maintaining the ideal penetration length of the 4” Snaplock rigid conduit of 2 inches. Create a “hook” by

bending the tab at the weakened or scored locations. Break-away when duct is fully supported in-place. Seal penetration with foil tape or sealant caulk.

- Snaplock pipe can be vented up (Diagram C) to a roof jack (see dryerjack.com), to a side-wall vent hood (Diagram D) or downwards to a crawl space or floor joist system with two elbows. Use the Model 4D or 3D to go down.

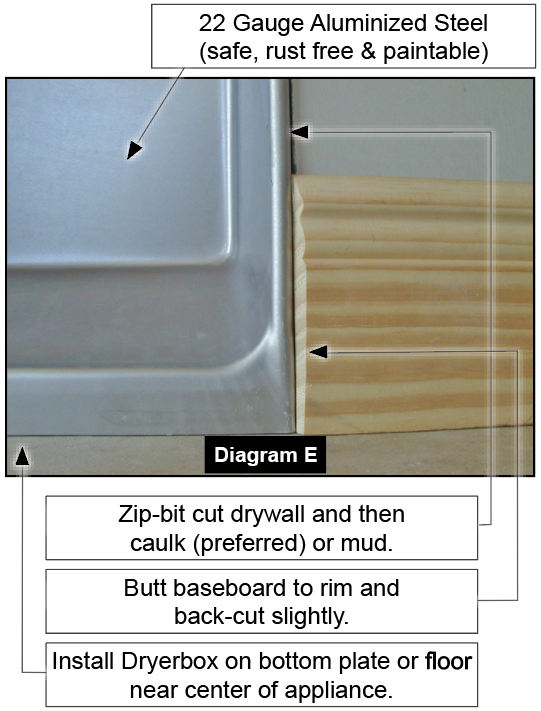

- Use a Roto-zip-bit router tool to cut the drywall leaving a caulk joint for the painter (Diagram E). It is best to caulk or mud this void (required for One-Hour Rating).

- The baseboard is best terminated with a tapered back-cut into the rim extension on either side of box (Diagram E).

- Exposed metal can be left unpainted or can be sprayed with an acrylic latex or oilbased (alkyd) paint when the rest of the wall, trim or baseboard is painted.

DB425 Installation Tips Video

Sku DB-425

(For Upward Exhaust Direction)

- 22 gauge aluminized steel weighing 4.14 pounds each

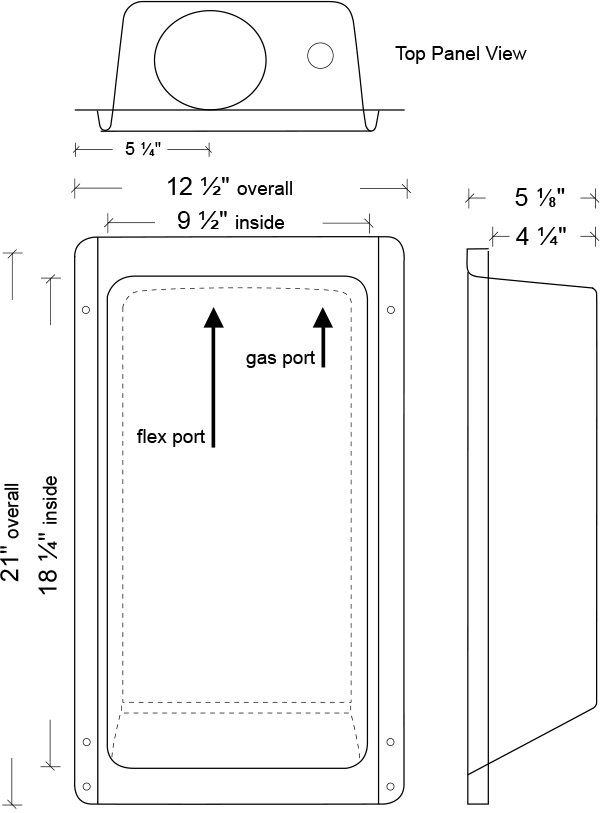

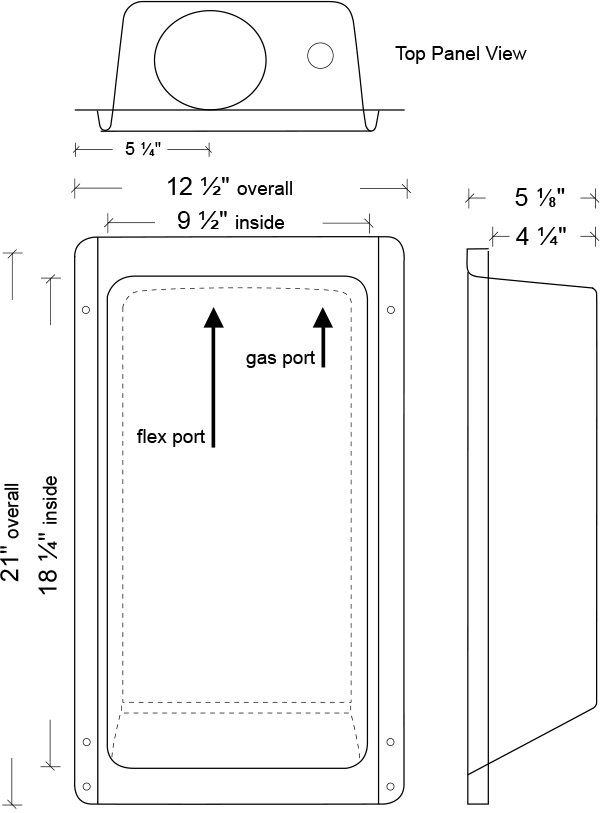

- Distance from nailing flange to rear of box is 4 1/4"

- Overall measurements: 21" h x 12 1/2" w x 5 1/8" deep

- Inside measures 9 1/2" wide x 18 1/4" tall

- Five units per carton, 36 cartons per pallet, ships as a class 70

Installation Instructions - PDF